So the good news/bad news, coming out of the Seattle Weavers’ Guild sale and knitting retreat at Port Townsend, was that my weaving inventory was seriously depleted (not complaining!). I had the Methow Valley Spinners & Weavers guild sale coming up. Also, both galleries where I show my work here in the valley have their holiday gift shows starting up. So it was time to get really busy!

I had been planning to try some simpler scarves using the idea of a “mixed warp” from a 1992 article in Handwoven magazine. The warp is, obviously, a mix of colors and textures and fibers – of which I have an abundance. Both coned yarns (from a friend who was closing out her studio), odd balls and skeins of hand-knitting yarns I have picked up over the years or at stash-reduction sales, etc. Also, the ends will not be twisted or braided but just left as fringes, which saves a lot of time in the finishing and also shows off the warp yarns at each end of the scarf.

This has been a learning experience and I have to say it is a lot of fun, and also I am getting better at it as I go along.

The first batch of 6 scarves were done on a mohair & mohair boucle warp using yarn I purchased wholesale from Fiber Trends in East Wenatchee. I wove them using a variety of wool knitting yarns, approximately worsted weight. They came out a little too short after washing but are OK for basic scarves to be worn under a jacket or coat.

Next I used a similar warp, also from Fiber Trends. This had originally been a bright “tequila sunrise” colorway but I recently overdyed it with indigo down at my friend Sara’s dye studio in Twisp, thus turning it more of a mauve color. I changed the sett from 6 epi to 8 epi and added more threads to the warp, for a total of 48 ends (i.e. 6″ wide on the loom).

These I wove with rayon chenille in 4 different colors. I wove them quite long on purpose (84″ – 86″ after washing) so they could be tied with my favorite method. Colors are delphinium, topaz, navy and silver chenille (from L to R).

long chenille scarves on a mixed mohair & boucle warp

Fold scarf in half and drape around neck. Put one end through loop. Give loop a half-twist and put the other end through.

Moving right along, I next used a combination of coned yarns and miscellaneous hand-knitting yarns in a gold, brown and magenta colorway. These I also wove long with 4 different yarns: black alpaca (Kid Silk accent stripes at each end), red baby alpaca, a chocolate colored rayon/metallic yarn, and purple rayon flake coned yarn held with a fine kid mohair yarn.

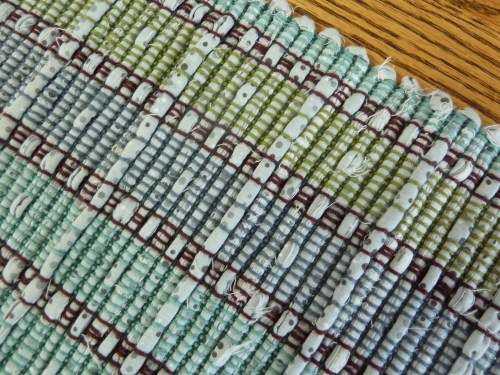

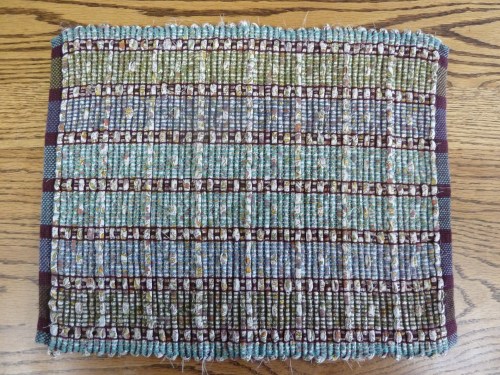

Next I decided to go for a more “normal” length scarf (about 70″ after washing) which also let me get 5 scarves instead of 4 from a 12-yard warp. The next warp was also a mix of coned yarns and hand-knitting yarns in a blue-green colorway.

Blue-green mixed warp on the loom

From L to R these were woven with: black alpaca (Kid Silk Haze stripes at ends), dark blue rayon/metallic yarn, teal rayon flake coned yarn held with kid mohair, cobalt rayon chenille, and Rowan black wool (bought at the knitting retreat stash reduction sale only a week before!) with accent stripes at each end:

Blue-green mixed warp scarves

So at this point, after 10 days I had completed 19 scarves and it was time for the Methow Valley guild sale, held just this past weekend. My friend Sara set up the display this year and did a fabulous job – she arranged things more by color than by type of weaving, so as you went around the room it was very stimulating visually, and lots to discover.

at the MVS&W Show & Sale, Nov 16-17, 2012

Again, the good/bad news is that I sold 10 of the 19 new scarves! My work wasn’t done…. I still had to bring things to the two galleries this week before leaving town for Thanksgiving.

Over the weekend I put on a new mixed warp using black, grey, white, some softer tones and a bit of gold glitter.

black & white warp on the loom

Again I wove 5 scarves, but one was bought by a friend who stopped by the house while they were still hanging to dry yesterday. So I only have pictures of four (hers was also the cream alpaca, though).

From L to R these were woven with: a gray-green 2-ply wool & silk yarn that I dyed several years ago for another project, white mohair and synthetic blend yarn, fine grey rayon tweed held with a variegated merino/kid mohair yarn, and natural cream alpaca from Henry’s Attic:

black & white mixed warp scarves

So that’s the 24 scarves finished in the last 2 weeks. I have wound these yarns for the next warp, and also show them on the warping board as I compose my palette:

on the warping board

Today I brought what I could to the Confluence Gallery in Twisp and Winthrop Gallery, and plan to keep at this through December as long as I am having fun with it and they are selling! Oh by the way I have been knitting a lot of my Mosaic Mojo hats too, but I will have to show those pictures in another post.

We’re off to the Coast tomorrow for 4 nights – Seattle for Thanksgiving with Rick’s mom and sister, then up to my Dad’s at Anacortes for the rest of the time, when we will also see my brother and sister-in-law on Camano Island.

Read Full Post »