That was the temperature when we got up at 7 am – minus one degree F, or over 30 below freezing. Yikes! Well it stays warm in the shop and apartment so I guess we got this place insulated pretty well. It has been clear and sunny and beautiful in the valley, although the continuing lack of snow is making us nervous.

The social event last weekend was the Confluence Gallery‘s annual holiday dinner up at The Barn in Winthrop. Now that doesn’t sound too elegant, but they decorated it in a cabin theme and it was really quite charming. The food was great, and this year they skipped the benefit auction so it was easier to socialize and mingle after dinner. Most of the attendees are volunteers, patrons or artists (or all three) so we have a lot in common. Rick and I had a great time and posed for our pictures in a sleigh:

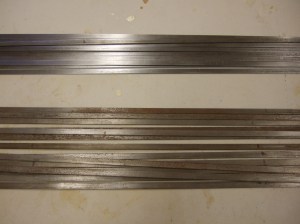

I have been weaving up a storm this week, having finished four shawls using a mohair boucle in colors that remind me of a parrot. It is a handpainted yarn from New Zealand, and the dyer called it “Lollipop”. It has proven to be a popular color, as I sold two at the weavers’ guild sale, and then two of these longer ones are on order. So then I did two more to have some for stock.

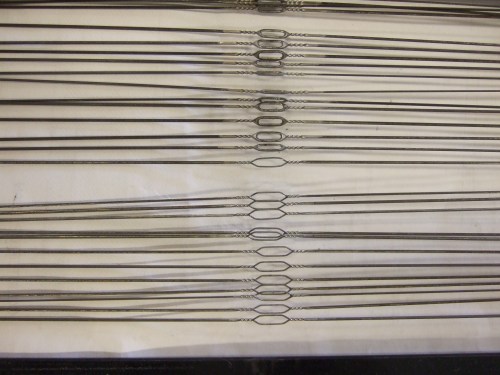

I also finished a knitting project – it is a wool vest that I started around the first of November. The pattern is “Veste Everest” by Veronik Avery, from the Fall 2005 Interweave Knits magazine. I used some yarn I had in stash, a Karabella yarn called “Aurora Melange.” It is a superwash extrafine merino in marled browns (or at least, I think “irrestringibile” means superwash…) and feels so soft and cushy and springy. I was worried I wouldn’t have enough after comparing the yardage of what I had with the yardage of the recommended yarn, so even though it is supposed to be a short vest and I am long-waisted, I finished it to the shoulders as written. At that point I had more than 2 balls of yarn left (out of eight) and it was really way too short. So I ripped it back to the underarms and added two more repeats of the cable pattern, or another 4 inches, before finishing it again. Now it is perfect on me, and I still had one whole ball left! Curious, but there it is.

The marled yarn somewhat obscures the cable pattern, but more so in the pictures than when you are looking at it in person. Not sure why that is, but I took about 6 shots trying to get better light and definition, to no avail.